Digital intelligence innovation helps refining and chemical companies transform and upgrade

[ad_1]

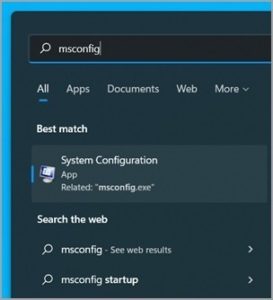

Safety, green, and efficiency have become the new directions for digital transformation of petrochemical companies. Huawei, the world’s leading information and communications technology (ICT) solution provider, focuses on technological innovation and practice in the ICT field. It has gathered excellent partners Anyuan Technology Co., Ltd. to assist the digital transformation of the petrochemical industry, and on December 13 The “Digital Innovation to Help Refining and Chemical Enterprises Transform and Upgrade” smart refining summit was successfully held at the Conrad Hotel in Tianjin.

Smart Refining and Chemical Summit site

Recently, Huawei released a new image slogan of “Digital Intelligence World, Just a Touch” for my country’s large, medium, small and micro enterprises. Fan Tao, general manager of Huawei’s China government and enterprise oil and gas business, said,“One touch”It’s like pressing a button – choosing an open and competitive “partner + Huawei”. In the petrochemical industry, Huawei has signed strategic cooperation agreements with companies such as Kunlun Digital and Petrochemical Yingke to jointly serve the digital transformation of petrochemical companies.At the same time, we have also reached a comprehensive cooperation with Anyuan Technology to jointly create chemical safety and emergency solutions; in the future, we will join more partners who have been deeply involved in the petrochemical field for many years to work together to better serve the petrochemical companies. Digital construction.“Instantly available”The digital intelligence world of petroleum refining. By closely integrating the infrastructure base with office production, we can achieve comprehensive collection, analysis and utilization of production and operation data, improve production efficiency, reduce operating costs, and enable more effective resource utilization and environmental protection.

Fan Tao, General Manager of Huawei China Government and Enterprise Oil and Gas Business

Professor Wang Sanming, a leading talent in the national “Ten Thousand Thousand Persons Plan” and Chairman of Anyuan Technology Co., Ltd., delivered a keynote speech on “Interpretation of the Development Trend of Digital Transformation of Enterprises in the Refining and Chemical Industry” and said that in building the “Intelligent Transformation to Digital Transformation” process in the refining and chemical industry Among them, first, we must pay attention to diagnosis first. Organize a team of experts to conduct in-depth corporate research, make a comprehensive “scan” diagnosis of the company, deeply and accurately understand the blocking points, difficulties and pain points in the company’s “intelligent transformation to digital transformation”, and at the same time “prescribe the right medicine” to propose a customized transformation plan and top-level planning. Second, we must pay attention to technology-driven development. By building a “new infrastructure” for the industrial Internet that integrates “basic platform + industry application + IoT terminal + logo analysis + security gateway”, we will strengthen the guarantee of all elements of the development of refining and chemical enterprises and realize the digital, networked and intelligent transformation of the entire chain. . Third, we must pay attention to business integration. By building an open and shared public service platform for the industrial Internet industry, we will promote the coordinated development of upstream and downstream enterprises in the industrial chain and achieve sustainable development in the refining and chemical industry. Fourth, we must pay attention to talent cultivation. By jointly building a “Chemical Safety Talent Training Base” that integrates industry and education with “teacher output + curriculum system + practical training center”, we will cultivate talents who understand both the profession and the industry, and provide more powerful support for the high-quality development of the refining and chemical industry. Talent protection.

Professor Wang Sanming, Chairman of Anyuan Technology Co., Ltd.

Tianjin Petrochemical strives to build a “high-end + intelligent” Tianjin base and create a smart factory 3.0 based on “digital twins” that “digitizes physical factories, visualizes on-site management, and intelligentizes production operations.” Gao Wenqing, chief informatization expert of Sinopec Tianjin Branch, delivered a keynote speech “Building 5G Intelligent Fully Connected Factories to Promote High-Quality Development of Enterprises” and said that the construction of smart factories comprehensively improves the efficiency of business decision-making and management, optimizes production and operation efficiency, and improves safety and environmental protection. management level, strengthen collaborative development capabilities, and empower the company’s high-quality development in an all-round way.

The content of building a smart factory based on digital twins includes: building a smart factory based on digital twins to integrate engineering construction and smart factory operations; building a data resource center based on digital twins to form a unified data base; building cloud and edge based on digital deliverables , end-to-end collaborative digital twin industrial Internet platform; build a “5G + Beidou” smart park, promote “machine replacement of people”, strengthen “intelligent security”, and improve production efficiency.

Gao Wenqing, Chief Information Technology Expert of Sinopec Tianjin Branch

Huawei insists on driving future development with innovation. Deng Bi, general manager of Huawei’s oil and gas industry refining and chemical field, delivered a keynote speech “Huawei Smart Refining Solution Helps Enterprises’ Digital Transformation Practice” and said that in the construction of smart factories, Huawei’s computing power, cloud, The fields of network and artificial intelligence have end-to-end advantages. 1. In the network field: Huawei’s 5G, data communications, Wi-Fi, industrial Internet and other technologies can help enterprises achieve efficient network connections and data transmission; 2. Industrial Internet platform field: Huawei can provide a mature industrial Internet technology platform , realizing a full-scenario solution for refining and chemical business from data governance, data models, and AI intelligent applications; 3. Digital Operation Command Center IOC: Through the results of data governance, large/medium/small screen collaboration can be realized to achieve real-time monitoring, management and command; 4. Project construction management of new plants: real-time visibility of progress, realizing simultaneous construction of “virtual” and “reality”; 5. Refining and chemical park safety: risk monitoring and early warning (intelligent video analysis); 6. Park emergency: prior, Full process command and dispatch during and after the incident.

Deng Bi, general manager of Huawei’s oil and gas industry refining and chemical fields

Li Dong, solution director of Anyuan Technology Co., Ltd., delivered a keynote speech “Industrial Internet + Smart Factory Solutions for Petrochemical and Chemical Enterprises” and said that in the process of building smart factories, refining and chemical companies should adhere to overall planning, step-by-step implementation, and efficiency. Driven and step-by-step principles. When building the technical capability system of smart factories, we start from the underlying industrial IoT sensing and gradually establish global sensing and early warning capabilities. By building a unified industrial Internet base platform and combining it with industrial mechanism models, refining and chemical companies can create industrial Internet service applications suitable for themselves.

Li Dong, Solution Director of Anyuan Technology Co., Ltd.

After the meeting, Qilu Petrochemical, Wudi Xinyue Chemical, Yizheng Chemical Fiber, Hengyi Petrochemical, Liaohe Petrochemical and many other chemical companies and colleagues in the petrochemical industry visited Tianjin Petrochemical’s “Dual Ports, Dual Cores, One Axis and Four Zones” smart petrochemical plant, and learned more In-depth study and exchange of Tianjin Petrochemical digital twin smart factory construction experience and results. Let every guest experience up close the safe, green and efficient results that digital transformation has brought to petrochemical companies, and work together to achieve the transformation and upgrading of refining and chemical companies through technological innovation.

Tianjin Petrochemical Site Visit

[ad_2]

Source link