Seize the commanding heights of the market Kaierda released a new generation of KC30 robot controller

[ad_1]

As one of the representatives of industrial robots in my country, Hangzhou Kaierda Welding Robot Co., Ltd. recently released a new generation of KC30 robot motion controller independently developed, which has greatly improved performance and reliability, and can be adapted to multiple robot systems.

The picture shows the picture of Kaierda’s new product launch conference

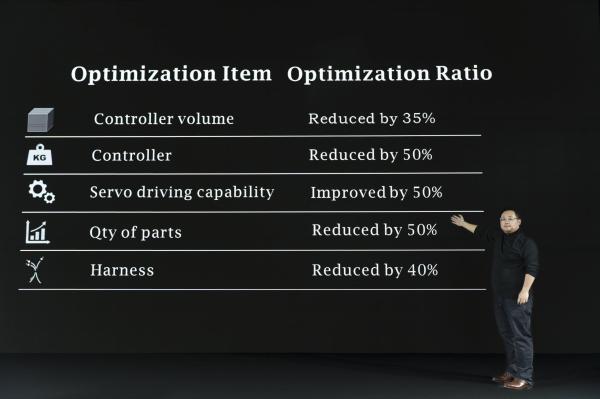

“Compared with the previous generation controller KC20, KC30 is more efficient, more stable, more accurate, more energy-saving, and more humanized.” Kaierda official introduction, the newly unveiled KC30 robot motion controller has been optimized in terms of appearance and structure, and at the same time , The hardware design has been improved, the rectifier unit replaces the transformer, and the Shenyuan module is optimized to achieve faster acceleration and deceleration of the robot. Through streamlining and optimizing the design, compared with the previous generation product KC20, the KC30 control cabinet volume is reduced by 35%, the weight is reduced by 50%, the driving capacity of the servo drive is increased by 50%, the number of wiring harnesses is reduced by 40%, the number of parts is reduced by 50%, and the reliability is further improved. .

The picture shows the picture of Kaierda’s new product launch conference

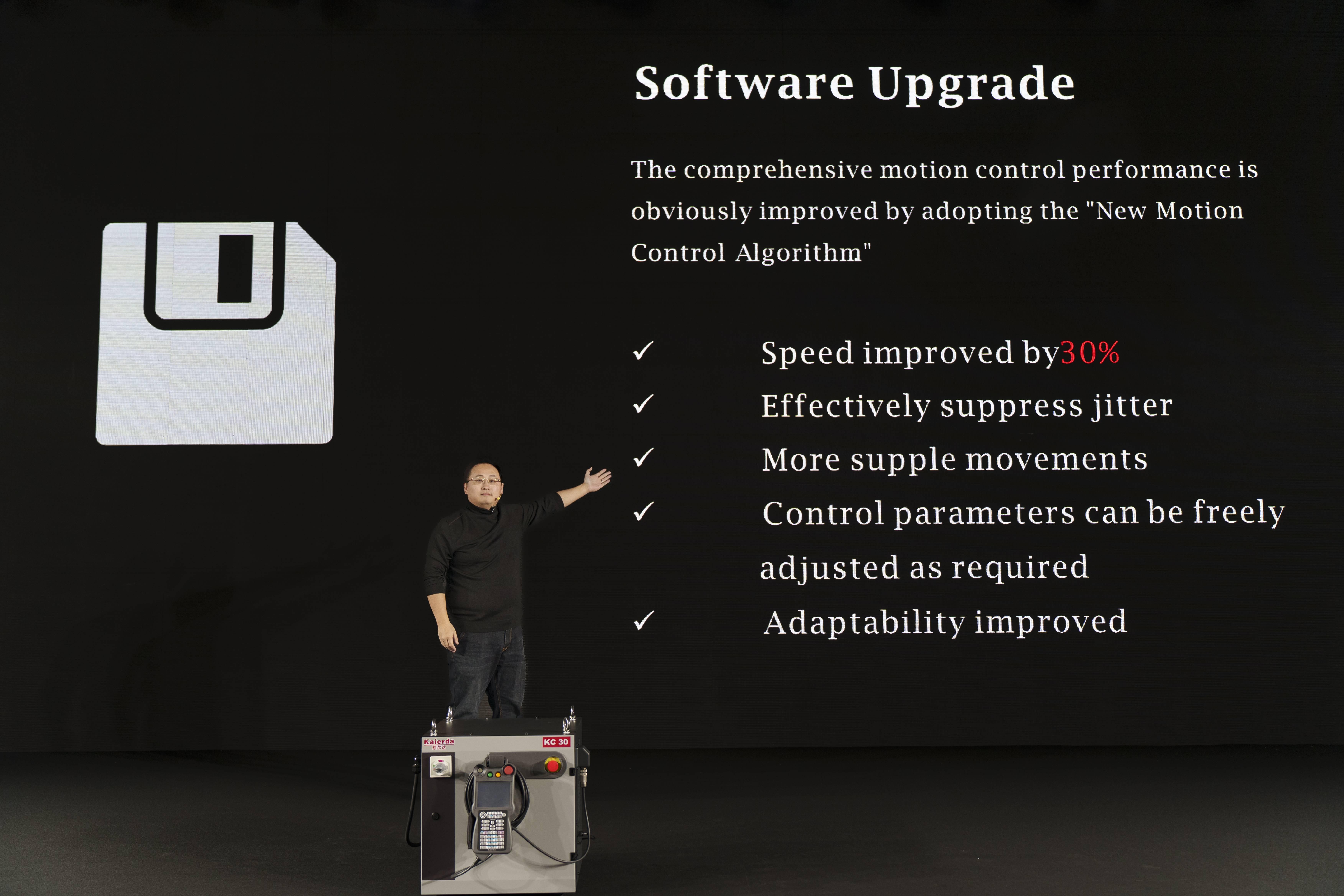

At the same time, the KC30 controller adopts the “new motion control” algorithm that can maintain vibration-free and smooth movements even under high-speed, high-acceleration and deceleration conditions, which increases the robot’s movement speed by 30%, and makes the movement more supple while effectively suppressing the vibration . General arc welding teaching applications can achieve the same or even faster cycle time as that of well-known overseas robot manufacturers.

The picture shows the picture of Kaierda’s new product launch conference

In addition, KC30 has stronger versatility, and it can directly drive any Kelda KR1440, KR2010, KP25 and other products without changing the driver accessories.

It is reported that the board-level CPU unit, launch unit, security unit, and 10 units in the KC30 controller are all independently designed.

As the control center of the mobile robot, the motion controller is the core component of the robot, and its development level represents the core technology level of a country’s robot industry. In recent years, Kaidar has devoted itself to the independent innovation and research and development of motion controllers. At present, it has reached the product level of international mainstream manufacturers in terms of motion control accuracy and applicability for completing complex tasks. It can not only effectively reduce product production costs, but also realize robot control systems. online expansion, rapid upgrade and maintenance.

At present, Kaierda series products are widely used in handling, grinding, bending, industrial welding and other industries. It is reported that Kaierda will release a high-speed, multi-functional welding servo arc welding system this year to further lead the market and help enterprises improve quality and efficiency.

[ad_2]

Source link