Focus on the new trend of flexible “smart” manufacturing in smart factories, and see how robots can help reduce costs and increase efficiency in the era of Industry 4.0

[ad_1]

As an important display and exchange platform for the electronics manufacturing industry, the Munich Shanghai Electronic Production Equipment Exhibition will be held at the Shanghai New International Expo Center (N1-N5&W5) on April 13-15, 2023. The exhibition site will attract nearly 800 innovative companies in the electronics manufacturing industry to join, and the exhibition scale will reach 73,000 square meters. Exhibits cover the entire electronics manufacturing industry chain, including electronics and chemical materials, dispensing and bonding technology, electronics assembly automation, test measurement and quality assurance, electronics manufacturing services, surface mount technology, wire harness processing and connector manufacturing, components Manufacturing, motion control and drive technology, industrial sensors, robots and intelligent warehousing, etc., one-stop, complete and efficient mastery of global cutting-edge technologies and products in the entire industrial chain of intelligent manufacturing and electronic innovation.

Photo source: The exhibition site of the previous Munich Shanghai Electronic Production Equipment Exhibition

Exhibitor Express—Gathering outstanding robotics and intelligent warehousing companies in the industry to help reduce costs and increase efficiency in the era of Industry 4.0

The 2023 Munich Shanghai Electronic Production Equipment Exhibition will gather industrial automation companies more comprehensively. Facing the ever-increasing demand for product customization and individualization, the exhibition will gather a group of outstanding robot companies at home and abroad, and look forward to human-machine collaboration. future.

Shanghai ABB Engineering Co., Ltd.

Booth No.: Hall N1 1308

ABB is one of the world’s leading robotics and mechanical automation suppliers. It focuses on providing a complete product portfolio of robots, autonomous mobile robots and mechanical automation solutions. Through ABB’s independent software design and integration, it creates higher value for customers. ABB Robotics and Discrete Automation has more than 11,000 employees in more than 100 locations in more than 50 countries around the world.

product description

SWIFTI CRB 1300 Industrial Collaborative Robot

ABB launched the new SWIFTI CRB 1300 industrial-grade collaborative robot, which further fills the gap between industrial robots and collaborative robots. Compared with other collaborative robots of the same level, the performance of SWIFTI CRB 1300 industrial-grade collaborative robots has been greatly improved. The maximum load has increased to 11 kg, the operating speed is as high as 6 times that of similar products, and the accuracy is 5 times that of similar products. Boost production efficiency by 44%. It is widely used in various production scenarios including loading and unloading of machine tools, palletizing, picking and placing, and screw tightening.

Shanghai FANUC Robotics Co., Ltd.

Booth No.: Hall N1 1100

Shanghai FANUC Robot Co., Ltd., jointly invested by FANUC and Shanghai Electric Group, inherits the technical advantages of FANUC, and provides products and mature and reliable products for the majority of industrial users with strong engineering integration and technical service capabilities. Advanced process plan and perfect technical service.

With its strong R&D, design and manufacturing capabilities, Fanuc Group, a global manufacturer of factory automation, provides users with highly reliable robots, robot automation engineering, all-electric injection molding equipment, high-precision EDM machines, small machining centers and automation Processing complete sets of projects to help our customers stand out in the fierce market competition. FANUC also provides software, control and vision systems and integrates them into the automation projects we develop.

product description

CRX-10iA

As a small collaborative robot, CRX-10iA has a maximum load of 10kg and a reachable radius of 1249mm. Its long-arm model CRX-10iA/L has a reachable radius of 1418mm. CRX provides users with accurate, flexible and safe human-machine collaboration solutions for the handling and assembly of small parts. CRX has excellent motion performance, and the maximum motion speed of the robot reaches 1000mm/s.

Zhongke Siasun Co., Ltd.

Booth No.: Hall N1 1520

Zhongke SIASUN Co., Ltd. is a subsidiary of SIASUN Robot Group established in Shanghai, and is committed to creating an international, platform-based and innovative benchmark in the robotics industry. The company’s business covers multiple collaborative robots, focusing on the independent research and development and production of collaborative robot serial products.

Zhongke SIASUN was recognized by the Ministry of Industry and Information Technology as a “specialized, special and new” small giant enterprise, and became the “invisible champion” in the field of collaborative robots, and was awarded “high-tech enterprise”, Shanghai “specialized, special and new” enterprise, Shanghai enterprise Technology Center, Shanghai Patent Work Pilot Excellent Unit, etc., was selected into the “Shanghai First Batch of Intelligent Manufacturing Solution Suppliers Recommended Catalogue”, won the first prize of Shanghai Science and Technology Progress Award, Shanghai May 1st Labor Certificate and other honors.

product description

DUCO Cobot

DUCO Cobot series products have built a product service system based on DUCO COBOT collaborative robot, DUCO AMR intelligent mobile robot, DUCO Mind intelligent application controller, DUCO Core operating system and DUCO Cloud cloud platform technology. The products have passed CE and SEMI certification, and have the characteristics of rapid deployment, easy operation, intelligence, safety, and stability. They are widely used in automobiles, energy, semiconductors, 3C, food and medicine, education and scientific research, and other industries. Products are exported to Southeast Asia, North America, Europe and other dozens of countries and regions.

Festival card robot

Booth No.: Hall N1 1300

As a high-tech enterprise, Jieka Robot actively deploys in the field of intelligent manufacturing by virtue of technical advantages such as integrated joints, integrated drive and control, visual recognition, drag-and-drop programming, and wireless teaching. Integrating robot technologies such as force control and vision, it improves the safety of human-machine collaboration and greatly improves the flexible manufacturing and automation of production.

AUBO (Beijing) Intelligent Technology Co., Ltd.

Booth No.: Hall N1 1600

As the national standard setter for collaborative robots, AUBO chip follow-up grasping and sorting production line integrates high-precision visual inspection, precise identification and dynamic grasping of workpieces, adaptive flexible sorting and intelligent planning and stacking, and comprehensively solves the aftermath of incoming workpieces. Automatic, fast, accurate and flexible sorting. The process requirements and process flow can complete the whole life cycle management of the workpiece and the automatic sorting of the whole process.

Advantages:

High-precision intelligent grasping, high recognition accuracy, compatible with multi-position and multi-type workpiece grasping;

High performance and fast response, fast capture time, can be combined with 3D vision and software system for secondary development, and agile deployment;

Cost-effective replacement of labor, improving production efficiency and releasing production labor.

Suzhou Elite Robot Co., Ltd.

Booth No.: Hall N1 1322

Elite Robotics established Suzhou Operation Center (8,700 square meters) in 2018, and Shanghai Zhangjiang Research and Innovation Center (2,400 square meters) in December 2020. The founding team all came from the Robotics Institute of Beihang University and studied under Professor Wang Tianmiao. Therefore, technology research and development is AI Lite’s genes.

From the underlying operating system, to embedded hardware and software, process packages and top computing power, to the modular joint technology of collaborative robots, Elite has achieved independent research and development except for the reducer. At present, ELITE is selling a collaborative robot product with 3 loads – EC series (3kg/ 6kg/ 12kg load). This series has accumulated a good reputation in the industry for its stable operation, smooth dragging, complete functions and high cost performance. And successfully introduced head customer collaborative robot projects including auto parts, 3C electronics, metal processing, home appliances, electric power, and new retail.

ELITE robot has the advantages of high cost performance, low self-weight and load ratio, and comprehensive guarantee of product stability. The company’s pre-sales and after-sales team has rich experience in using robots and a deep understanding of the scene. It has already deployed more than 3,000 collaborative robots with practical capabilities. Through “machine substitution” and “man-machine collaboration”, the single-station automation transformation has been realized, which has empowered the factory to reduce staff and increase efficiency.

Nanjing Silicon View Automation Technology Co., Ltd.

Booth No.: Hall N1 1500

Silicon View Technology was established in Nanjing, Jiangsu Province in 2012 by a scientific research team returned from overseas, and has been committed to the R&D, production and sales of active sensing robot units. Silicon View has a research and development team composed of many overseas doctors. After years of development, the Silicon View team has accumulated profound knowledge of intelligent robot units and rich industry experience, and has grown into a leading domestic collaborative robot system integrator. Silicon View provides customers with integrated intelligent robot system solutions from robots, end tools, smart sensors and artificial intelligence software. We are especially good at complex assembly applications using 3D, 2D, vision, force control closed-loop and intelligent path planning.

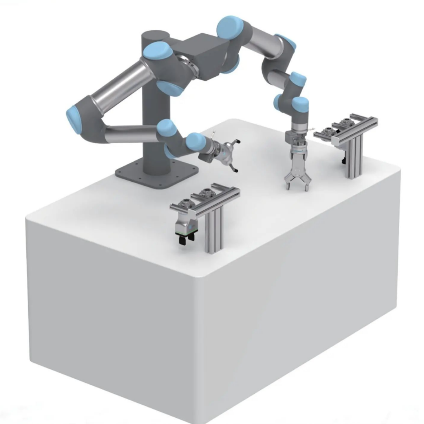

product description

Dobby Assembly Robot Cell

Multi-arm integrated motion planning assembly system

Heterogeneous and diverse end effectors for complex assembly tasks

With visual position determination and detection function

Highly flexible force control closed loop realizes elastic assembly

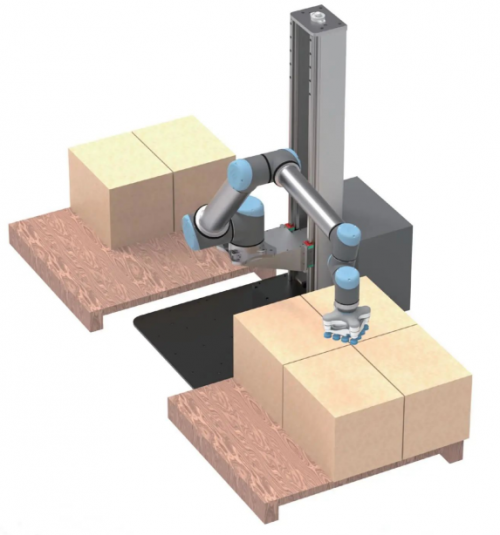

Intelligent palletizing robot unit

Integrated 7-DOF palletizing unit

No need to write palletizing programs

Graphical operation interface, automatic production palletizing program

Combined with 3D vision, mixed palletizing and depalletizing can be realized

Composite Mobile Robot Cell

Laser navigation autonomous mobile compound robot is equipped with single arm or double arm 6 degrees of freedom robot arm 3D vision and artificial learning intelligent force control closed-loop terminal machine care, mobile operation and other human-like automation tasks.

Laser Navigation Autonomous Mobile Composite Robot

Equipped with single-arm or double-arm 6-DOF robot arm

3D Vision and Artificial Learning Intelligence

Force Control Closed Loop End

A powerful carrier for human-like automation tasks such as machine care and mobile operations

Luoshi robot

Booth No.: Hall N1 1358

Founded in 2015, Luoshi Robotics focuses on the R&D, production and sales of series products such as multi-joint industrial robots and collaborative robots. , quickly provide customers with smarter, more efficient, safer products and automation solutions and other services.

The company is headquartered in Beijing, and has established robotics R&D centers in Beijing, Tokyo, Wuhan, and Shandong. More than 80% of the R&D personnel are graduate students or above, and most of them are from well-known universities such as Tsinghua University, Peking University, Beihang University, Zhejiang University, and Huake University. It has an intelligent manufacturing future factory with an annual production capacity of over 50,000 units in Shandong, China, and has established a global sales, technical support, and automation solution service system. The company attracts outstanding talents from all over the world and continues to invest heavily in research and development. So far, it has obtained more than 300 domestic and foreign research and development patents and technology awards, and has been recognized by many parties in the industry.

product description

A new generation of high-speed robots “Fast and Almighty” NB12 series

There are 6 products in the NB12 series robots, 4 of which are six-axis robots, with loads of 10kg, 12kg, and 16kg respectively, and arm spans ranging from 1053mm to 1602mm. In response to the plane handling scenarios in PCB and other industries, Luoshi also customized and developed three-axis robots and four-axis robots, both of which have a maximum working radius of 953mm.

Features and advantages:

New design, stronger protection. The NB12 series adopts a full-cast aluminum body design, which is 30% lighter than products of the same level. It is lighter in weight and has smaller support reaction force among similar products. , the motor cable is built-in, the body has a high protection level of IP67, and is equipped with a high-protection dual-circulation heat dissipation control cabinet of IP54, which can cope with wet and other coolant spray scenarios, reduce the maintenance cost of equipment due to water ingress failures, and improve the efficiency of the production line , to ensure that the robot can cope freely in harsh environments.

Compact structure, easy deployment. The NB12 series adopts the form of built-in motor and cable, and the structure is more compact. The installation size of the base is only 250x250mm, which is 47% smaller than that of products of the same level. You can choose any installation method such as front installation, side installation, and flip installation, and can be flexibly deployed in small spaces. , Improve installation convenience. The NB12 series single-axis rotation range is larger, the working blind area is smaller, and it completely covers the mainstream scene applications of small-load robots.

High precision and high speed, high production efficiency. NB12 series OptiMotion & TrueMotion dual technology guarantee, repeated positioning accuracy of ±0.03mm, 20% increase in operating speed, rapid production and greatly increased production capacity.

Authoritative certification, escort. The NB12 series has passed a variety of international authoritative certifications, including CE, UL, CR, KCS, EAC, etc. Parts and robots have undergone strict quality inspections to ensure high-quality production.

Faoyiwei (Suzhou) Robot System Co., Ltd.

Booth No.: Hall N1 1350

Faoyiwei is the first collaborative robot company in China to realize the independent research and development of all core components. It is committed to being a popularizer of collaborative robots and making robots a basic tool.

Our in-depth chip-level research and development and innovative supply chain model provide products with better performance for various industries. “+” affordable products;

We grow together at a high speed with partners and customers, and provide excess value to partners and customers. We have launched free online and offline training courses for the public to reduce the use threshold and entry cost of customers, and provide integrators with free application case technologies in various industries. In order to promote the continuous empowerment of terminal applications in various industries.

Create the future with Faol! We will strive to be a practitioner of “robot +”, deeply cultivate the road of robot popularization, actively extend the application boundary of collaborative robots, realize Fao INSIDE in various application scenarios, and help more enterprises realize automation upgrades.

product description

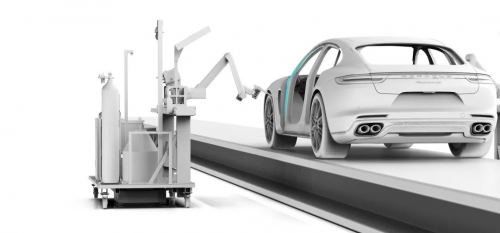

Welding Robot Workstation

The flexible programming-free welding technology, combined with standardized structural components and movable overall design, significantly improves the intelligence of welding production lines for small and medium-sized enterprises, solves the difficulty in recruiting and employing workers currently faced by the welding industry, and helps enterprises significantly reduce operation and maintenance costs. Relying on AI intelligence and big data technology, the active exploration of remote welding for future enterprises in the 5G environment has been completed.

Palletizing robot workstation

One-stop palletizing workstation with six-axis collaborative robot (FR10, FR20). Simple programming, ready to use; with modular joints, it can be used out of the box without integration or wiring.

main feature:

No need for safety fences; no need to add sensors; easy to operate and simple to program; can be used with pallet jacks or forklifts.

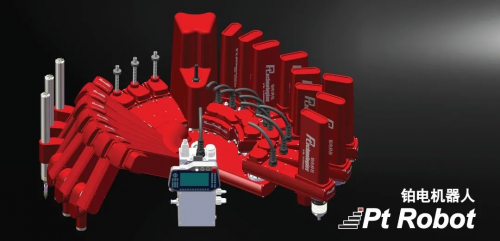

Platinum robot

Booth No.: Hall N1 1226

Platinum Robotics Co., Ltd. is a positive technology-oriented robot company that advocates originality. Through years of practice and accumulation, Platinum Electric has “high speed (4Hz standard cycle)”, “high precision (sub-silk repeat positioning accuracy)” and “high reliability (over 100 Hundreds of millions of actual battles)” and “full product line (500+ standardized models)” robots can provide integrators with efficient and reliable solutions.

product description

Platinum Electric Ultra-precision Assembly Robot

For the assembly of micro-screws below M1.2 in 3C and other electronic industries, piezoelectric control of micro-dispensing glue, PCB plug-ins of electronic components, etc., the tolerance capability of wire-level ultra-precision assembly within 0.1mm, and high-precision quality Robotic automation demand scenarios for detection and measurement. After more than ten years of R&D and innovation, more than 10 billion application practices and dozens of rounds of product iterations, Platinum Robotics has launched 4 series and 15 categories to meet these needs, with more than 500 products. There are 3, 4, 5, 6, and 7 degrees of freedom general-purpose robots and ultra-precision assembly-specific robots combined with various processes.

The repetitive positioning accuracy of Platinum Innovation α series SCARA robots has fully entered the sub-wire level of 0.01mm, and the position accuracy of Platinum Innovation β series vertical multi-joint robots has fully entered the silk level within 0.10mm. From then on, these ultra-precise assembly scenes There is a better chance to get rid of the high dependence on skilled operators.

Shenzhen Moying Technology Co., Ltd.

Booth No.: Hall N1 1550

Shenzhen Moying Technology Co., Ltd. is a platform company focusing on robot research and development and system application development and deployment. It provides integrated fusion technology and full-scenario high-performance digital transformation solutions for the robot ecological field. The company is based on AI, big data, Internet of Things, Cloud computing, digital twins and other technologies, customize digital solutions for different enterprise management processes according to customer enterprise conditions, build technology bases, accelerate the realization of intelligent and digital transformation of humans, robots and data information, and create exclusive, efficient, and low-cost operation and maintenance A new ecology of digital and intelligent symbiosis, intelligent and intelligent manufacturing.

product description

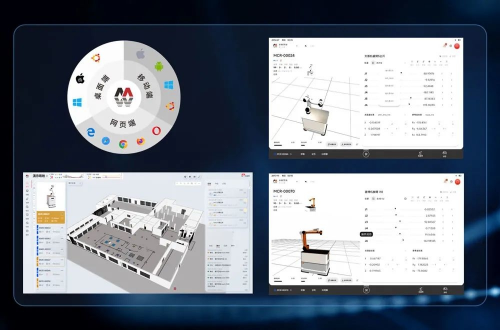

Moying Technology Tiangong Mobile Collaboration System

Moying Tiangong Mobile Collaboration System is a system platform for robot development and application management with 100% low-code, high reusability, high migration, multi-level, multi-dimensional and multi-form, fully open docking and integration.

It has core modules such as monomer integration, group collaboration, rule processing, process arrangement, digital twin, performance tracking, etc. It can organically link all automated production equipment and different types of robotic equipment, and can connect to platforms such as MES, WMS, MCS, and OMS. Realize the digital upgrade and management of the whole site.

Relying on the system, robot companies and automation integrators can quickly realize the development of robot functions and the deployment of the overall production line of robots.

Moying Mobile Collaborative Robot

Moying Technology, as a pioneer of mobile collaborative robots, relies on the integrated control technology of robots to realize the organic integration of multiple modules such as mobile chassis, robotic arm and vision, and realize the functions of object handling, loading and unloading and detection. Relying on Moying Tiangong mobile collaboration system, it can realize the cooperative operation of multiple devices and realize the automatic production of flexible matrix production line.

Core Technology:

An intelligent control center – collaborative work is faster

A centralized independent controller controls the AMR, robotic arm, vision and other modules in a unified manner. It has the integrated function of simulating artificial “hands, feet, and eyes”, and the collaborative operation is more stable.

Seiko design – easier to operate out of the box

Sensitive operation, stable driving, zero modification, easy operation. The device is ready to use out of the box, low-code deployment, and commissioning can be completed quickly.

The factory is equipped with Moying Tiangong Mobile Collaboration System—mixed scheduling is more flexible

Relying on the system, it can realize multi-machine scheduling, quick deployment, data integration, and adapt to flexible production operations in all scenarios.

Suzhou Paixun Intelligent Technology Co., Ltd.

Booth No.: Hall N1 1112

Founded in 2014, Passion Intelligence is committed to providing digital and intelligent production-oriented “intelligent line side warehouse products + industry closed-loop overall solutions” for discrete manufacturing customers. The main products include intelligent warehousing equipment, intelligent handling equipment, material visual registration & detection & inventory system, mobile IoT storage terminal, material execution system iMHS, iWMS, WCS, RCS and other software and hardware for production process and intelligent factory integrated solution .

Passun Intelligent links the material flow through innovative standardized line side warehouse products, opens up the data flow through the self-developed software system, and expands to the upstream and downstream of the production link through the integrated service model, providing customers with a smart supply chain throughout the entire production process Solutions, to create a new infrastructure for the transformation and upgrading of “digital intelligence” for enterprises.

Up to now, the company has helped many Fortune 500 companies to successfully build “lighthouse factories”, with more than 200 projects in operation, and customers cover semiconductors, new energy, national defense and military industry, consumer electronics, automotive electronics, rail transit, electric power and other fields. enterprise.

product description

Large-capacity dual-channel intelligent storage equipment

Efficient storage: “one item, one code, one storage space”, small footprint, large capacity, unmanned, precise and intelligent management

Intelligent management: Realize the digital intelligent management of the whole process of electronic material storage, picking, delivery, inventory, etc.

High-precision sorting: dual-channel collaborative operation, accurate material picking in batches, improving efficiency, reducing labor intensity, and reducing the risk of wrong materials

Data fusion: seamless integration with ERP, MES, WMS and other systems

Full specification vision automatic labeling machine

Batch labeling: support multi-specification materials such as 7/13/15 inch trays

Intelligent and efficient: It only takes 2-6 seconds to complete the original label code reading, customer label printing, rotation positioning, customer label attachment and other functions

High precision: forward-looking modular and integrated design, using vision with intelligent manipulator

Intelligent material tower

Multi-effect storage: modular and integrated design, only 1 square meter is needed to realize all the functions required for daily storage/management of materials, such as: automatic access, batch retrieving, etc.

Temperature and humidity control: It can realize the temperature and humidity control of temperature and humidity sensitive components, and avoid the quality of materials being affected by improper control. Data fusion: Data exchange with MES, ERP, etc. can realize the integration of electronic manufacturing production lines.

*The content and pictures of the above exhibitors are provided by the relevant exhibitors

[ad_2]

Source link