Grasping the growth opportunities in the era of flexible intelligence, Jieka Robotics was selected into the list of “Shanghai Key Service Unicorn Enterprises”

[ad_1]

On February 27, the 2023 Shanghai key service unicorn (potential) enterprise list press conference and special service matchmaking event were successfully held.A total of 25 companies were selectedList of “Shanghai Key Service Unicorn Enterprises”, Jieka Robotamong them. As one of the enterprises that the Shanghai Municipal Government focuses on, Jieka Robotics promotes industrial upgrading with high-quality development with the support of government policies, resources, and services.

The development of the robot industry has a history of nearly a hundred years, and Jieka Robotics has only been established for nine years. Why can it beat the tide and become a unicorn?

As countries have successively entered the Lewis turning point, enterprises must improve productivity and carry out digital transformation as important measures to deal with changes in market models. Jieka Robot keenly captured this information, chose the collaborative robot track, and is committed to reconstructing productivity with more flexible and intelligent collaborative robots, empowering and increasing efficiency on the supply side, and assisting the digital transformation of enterprises.

Accelerated changes in market demand

?Collaborative robots open up new dimensions of automation

With the continuous advancement of technology and the improvement of material level, the demand iteration of consumer terminals is constantly accelerating. From electronic products to household appliances, and even large-scale commodities such as automobiles, the life cycle of products has been shortened to varying degrees, and the production demand has shifted from large-scale and standardized to multi-variety, small-batch, and customized. This trend is forcing the manufacturing end to reform. Enterprises need to have the ability to quickly change production lines and deploy flexibly. Practice has shown that the introduction of collaborative robots for flexible automation transformation by enterprises has greatly helped them improve the competitiveness of their production lines.

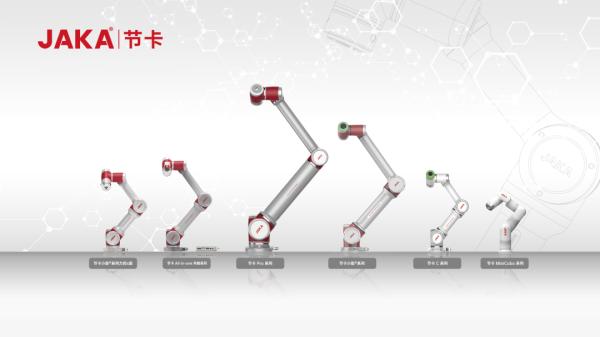

The base diameter of the whole series of Jieka robots is between 124mm-246mm, and the size is small; it has multiple safety protection mechanisms, high safety, and can live in the same space with humans and work collaboratively; functions such as graphical programming, drag and drop teaching, and easy operation Simple, which greatly reduces the threshold for using robots; easy to install, plug and play, and can be quickly deployed again. Based on the above advantages,JAKA robots can be deeply embedded in all aspects of production, with flexible layout, meeting the needs of rapid production and line changes, reducing the cost of switching non-standard production lines, and promoting the evolution of the manufacturing industry in a more flexible and intelligent direction.Enter.

In an industry with a high degree of automation and a large production scale such as automobiles, Jieka Robot has established cooperation with global auto giants such as the Toyota industry chain to create benchmark projects,Use flexible production methods to penetrate into all aspects of auto parts production, and efficiently perform tasks such as three-pin shaft grinding, inner star wheel grinding, and small-piece raw processing, such as loading and unloading, screw locking, testing, gluing, and assembly, to further liberate workers Hands, open up a new dimension of automated production.

In 3C electronics, metal processing and other industrial fields, there is a large demand for labor, the working environment is not good, and facing the dilemma of difficult recruitment and rising labor costs year by year, enterprises urgently need “machine replacement”. Jieka robots can efficiently replace manual work, and an average of one robot can replace 2-3 people, helping enterprises reduce labor costs and improve production efficiency. When workers perform repetitive and tedious work, they may make mistakes, resulting in insufficient yield rate, and manual operation also has the problem of insufficient product consistency. Jieka robots have high repetitive positioning accuracy, and can work 24 hours without fatigue, effectively ensuring product quality.JAKA Robot accelerates productivity reconstruction through flexible automation solutions.

automation to digitization

Smart terminal for execution and information fusion

In social life, mobile phones have become an extension of people. In manufacturing, it can be said that collaborative robots are an extension of workers.Jieka robot is not only the executor of production actions, but also an intelligent terminal for information fusion.

In the case of primer coating for automobile corner windows, the Jieka robot communicates with PLC (Modbus TCP), judges the size and number of windows according to different sensor signals received, runs different subroutines, and flexibly switches for primer operation.

In the SMT placement process of the 3C electronics industry, the degree of digitalization of manual picking is low, it is difficult to synchronize inventory, and congestion of multiple production lines queuing up to pick materials often occurs. Based on 5G network, AI, big data and other technologies, Jieka robot integrates AGV+ Jieka robot+production line terminal interface to complete the automatic distribution of raw materials, and connects through the automation system to integrate the fragmented workshop and warehouse information in the past to achieve accurate digitalization manage.

In order to further empower customers through digitalization, Jieka Robot also launched an OTA smart service platform, using cutting-edge technologies such as the Internet of Things, cloud computing, artificial intelligence, and big data analysis to realize the efficient interconnection of people, equipment, and services. The platform provides users with a full range of robot health management services through the 6C services of cloud monitoring, cloud analysis, cloud prediction, cloud alarm, cloud diagnosis, and cloud reminder. Users can control the running status of the robot at any time, provide support for production decision-making, and accelerate the process of industrial digitalization.

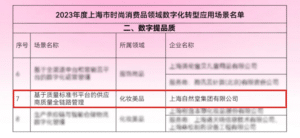

This selection into the list of “2022 Shanghai Key Service Unicorn Enterprises” fully proves the government’s recognition of the development strategy, technological innovation, and ecological construction of Jieka Robotics. Taking root in Shanghai, Jieka Robot has continuously achieved breakthrough growth and won many awards. It has successively won the first prize of Shanghai Science and Technology Progress Award, the title of “Science and Technology Little Giant” in Shanghai, as well as the specialized and special new “Little Giant” and key “Little Giant” enterprises Title, China Patent Excellence Award, selected as Shanghai Intelligent Robot Benchmark Enterprise and Application Scenario, and 2022 National Intellectual Property Advantage Enterprise. Facing the future, Jieka Robot will conform to the development potential of the times, continue to use innovation and development as the engine, and break through the waves.

[ad_2]

Source link