Focus on SMT complete line equipment, meet in Munich Shanghai Electronic Production Equipment Exhibition in April

As an important display and exchange platform for the electronics manufacturing industry, the Munich Shanghai Electronic Production Equipment Exhibition will be held at the Shanghai New International Expo Center (N1-N5&W5) on April 13-15, 2023. The exhibition site will attract nearly 800 innovative companies in the electronics manufacturing industry to join, and the exhibition scale will reach 73,000 square meters. Exhibits are all-encompassing, covering the entire electronics manufacturing industry chain, including electronics and chemical materials, dispensing and bonding technology, electronics assembly automation, test measurement and quality assurance, micro-assembly, electronics manufacturing services, surface mount technology, wire harness processing and connectors Manufacturing, component manufacturing, motion control and drive technology, industrial sensors, robots and intelligent warehousing, etc., one-stop, complete and efficient mastery of global cutting-edge technologies and products in the entire industrial chain of intelligent manufacturing and electronic innovation.

Picture: The exhibition site of the previous Munich Shanghai Electronic Production Equipment Exhibition

Spoilers for some exhibitors, sneak peek

2023 Munich Shanghai Electronic Production Equipment Exhibition will bring together FUJI, Guangshidai, YAMAHA, Europlacer, Panasonic, Yishi Trading, MYCRONIC, KURTZ, Rehm Thermal, Zhuhai Zhixin, Esmot, Esther, Luyuan, Intuo , Quick, Axis, Nitto, Anda, Desen, MacDermid Alpha, Indium Corporation and other important equipment companies for SMT production lines. They will showcase their top technologies and products in SMT application fields such as automobiles, industry, and communication electronics.

Suzhou Guangshidai Electromechanical Equipment Co., Ltd.

1. YRH10 hybrid placement equipment

It is most suitable for the production of module products, and can realize the mixed mounting of semiconductor components and SMD components; the in-line mounting head with a scanning camera can complete the action from picking up to mounting in the shortest distance; it supports electric feeders and matches sufficient It is optional and can cope with various production processes at the same time; both versatility and production efficiency are improved.

2. YRM20 high-end high-efficiency module placement machine

Extremely improved “single placement head solution” achieves the fastest placement speed of 115,000CPH in the 2-beam and 2-placement head level; the ultra-high-speed turret-type RM placement head that can achieve 115,000CPH placement capacity and the in-line type for heterosexual components FM placement head; standard matching can maintain various functions of high-quality placement. The non-stop tray feeding device eATS30 realizes efficient tray component replenishment and non-stop production. It is an all-round placement with excellent productivity and versatility machine.

UERBIZ Automation Equipment (Shanghai) Co., Ltd.

1. atom series

The ii-A2 modular pick and place machine is equipped with a pair of high-speed Pulsar tube placement heads, has 164 8mm feeder positions, can handle all compact module package components from 01005 to 13mm x 13mm x 7mm size, and is designed to provide high speed , fully intelligent and highly integrated productivity. With a placement speed of up to 50,000cph, the ii-A2 takes production line capabilities to the next level by providing an optimized placement process that maximizes the performance and throughput of Europlacer equipment. The Pulsar high-speed placement head has 8 smart nozzles for pick-up. The ii-A2 is configured with two of these innovative placement heads, and in particular advanced non-lubricated material technology reduces maintenance costs and service interventions. Pulsar’s lightweight construction allows it to surpass all previous Europlacer platforms in terms of speed and acceleration. The ii-A2 helps deliver maximum productivity while requiring a minimal footprint. Modularity allows these machines to perform specific tasks, allowing production engineers to optimize resource allocation and maximize production line utilization.

?2. iineo series

Prepare for future challenges The iineo platform in the Europlacer range of pick and place machines has further improved features such as large feeder capacity, largest board size and largest component height. This platform adopts Europlacer’s unique integrated intelligence TM technology. In addition to Europlacer’s proven core functions (efficient and flexible rotary placement head, intelligent feeder, 3DPS, and powerful software), it also introduces linear motors and digital cameras. Wait for new technology. iineo allows 24 different machine combinations. The system can accommodate a maximum of 264 8mm reel positions, while the built-in tray area can accommodate 10 JEDEC trays. iineo can also be configured with one or two 30-layer chip tray loading cabinets. Depending on the configuration, the maximum placement rate is from 14,000 to 30,000cph, the maximum board size is 1,610 x 600mm, the component range is from 01005 to 99 x 99mm, and the maximum component height is 34mm. Other possible options include: Archimedes screw dispensing head, component electrical test, fixed camera, automatic track adjustment, special nozzle automatic replacement slot, etc. The new platform also includes innovative software products: The Multi-Assortment Optimization Package is a powerful optimizer for multi-assortment production in one setting. Because feeders are used in high volumes, this software package helps eliminate frequent changeovers, ensuring lead time and quality performance. Wireless inventory tracking provides full visibility and quick access to component inventory, including components loaded into feeders and storage racks.

3. SP700 series

The SP710avi combines Speedprint’s promise of high performance and high reliability. The system is designed to handle the rigors of high-volume SMT production, while remaining adept in high-mix environments. The SP700avi with the Auto Dispenser (ADu) is the SP710avi. The Automatic Dispenser (ADu) with dual syringes allows users to incorporate this functionality on the press, eliminating additional capital expenditure. The SP710avi features unique down/down vision to help optimize board stencil alignment, providing 20micron, 6 sigma performance at 2Cpk. Additionally, screen printers do not need to compromise calibration due to fiducial quality issues.

Mycony Electronic Equipment (Shanghai) Co., Ltd.

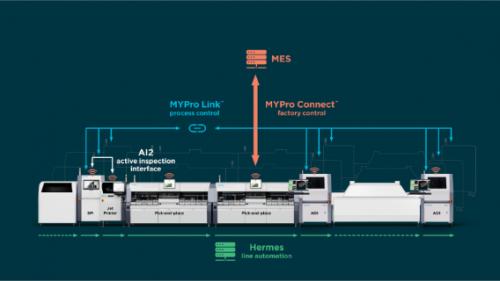

1. MYPro series full software driven SMT production line (new product)

Future production is smarter. With MYPro Line™, you can print perfect solder joints at top speed; enable continuous production with intelligent storage and active refill; use 3D inspection systems to avoid defects, and monitor and improve your process over time. This is Mycronic’s best choice for a complete integrated manufacturing solution. We can simplify production scheduling and improve production efficiency through more intuitive process control, Hermes support and new Kanban analysis software. Put future production back under your control.

Suzhou Aisimute Machinery Equipment Co., Ltd.

1. Online vacuum reflow oven

In 2009, SMT was the first in the world to develop and produce an online vacuum reflow furnace, which solved the problems of soldering voids and production efficiency that plagued customers, ushered in a revolutionary change in the global surface mount vacuum welding process, and has won many awards since 2009. International Innovation Gold Award.

Zhuhai Zhixin Automation Technology Co., Ltd.

1. JS-680

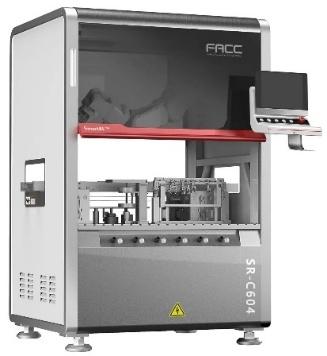

With machine vision, motion control and deep learning as the core, it is equipped with a six-head working unit, and the plug-in speed reaches 6000cph (beat 0.6s/piece), which has reached the leading level in the industry. In the past 6 years, FACC has focused on the research and development of “special-shaped plug-in machines”, deeply understood the application-side scenarios, and sincerely cooperated with customers to discuss new processes and technologies, and developed a wealth of feeding systems and clamping devices to solve problems for the industry. The problem of irregular incoming materials has been solved.

2. Robot special-shaped plug-in machine

The SmartAI SR series robot plug-in platform adopts robot and dual vision functions for plug-in, and also has leading performance, rich grippers and suction cup options; the overall equipment adopts a modular and flexible design, which is easier to maintain while plug-in. Regardless of realizing mass production or handling a large number of mixed small batch products, the SR series solutions can meet the needs of customers and help customers seize the opportunity in the fierce competition.

Nitto Technology

Ridong Technology was established in Hong Kong in 1984, established an industrial park in Shenzhen in 1999, and was listed in Hong Kong in 2000 (stock code 0365.HK). It is the core enterprise of Xincheng Technology Holdings. Ridong Technology has focused on SMT intelligent equipment and semiconductor back-end applications for more than 35 years. The company’s self-developed products such as reflow soldering, wave soldering, selective wave soldering, vertical furnaces, and IC bonding machines have always maintained technological leadership in the industry. Status. The company is equipped with a modern industrial park and advanced research and development experimental facilities, has strong system integration capabilities in research and development, design, production, automation, and information equipment manufacturing, and has a sales and service network all over the world. It is a leading enterprise in China’s intelligent equipment industry .

1. IC bonding machine

Ridong Technology IC bonding machine is a general-purpose bonding equipment that can achieve high-precision, high-speed chip bonding. Its strong adsorption and force control capabilities can be used for bonding a variety of different chips.

Support automatic nozzle replacement;

Support a variety of different glue supply methods (glue dispensing, glue dipping, painting glue);

Support multi-layer stacking and loading;

Support system-in-package;

Ultra-thin chip mounting technology;

Ultra-small chip bonding;

Realize quick line change;

Ridong Technology IC laminating machine can be used for product packaging of integrated circuit IC, WLCSP, TSV, SIP, QFN, LGA, BGA and other processes, such as optical communication modules, camera modules, LEDs, power modules, power devices, automotive electronics, 5G radio frequency, memory, MEMS, various sensors, etc.

2. Nitrogen reflow soldering

Features:

The whole machine adopts modular structure, which is convenient for cleaning and maintenance;

Anti-deformation structure design of guide rail, stable and reliable transportation;

Partial nitrogen filling or full nitrogen filling can be used, and the furnace is designed in a closed manner, so that the nitrogen is not easy to lose and the oxygen content is reduced;

Furnace flux recovery adopts multi-stage filtration with independent recovery box;

Equipped with high-precision oxygen analyzer, multi-flow meter adjustment, more accurate and stable control;

With Secs/Gem communication protocol interface, it can meet the needs of 5G integrated circuit semiconductor chip welding.

The latest cooling technology, the bottom cooling system can reliably and efficiently cool complex PCB boards and reduce component stress effects;

3. Double electromagnetic pump selective wave soldering

Features:

Double electromagnetic pump design, double the efficiency;

High-precision drop nozzle imported from Germany;

Stable peak height, extremely low maintenance rate;

The welding status is displayed throughout the process, and the distance between the two nozzles is automatically adjusted;

Support online/offline programming, welding parameters can be set independently for each welding spot;

Won the Gold Award of the 4th Industrial Design “Red Sail Award”

Kaga Electronics (Shanghai) Co., Ltd.

1. Small intelligent selection of wave soldering

1. Specially designed point-type flux spraying 2. Selective spot welding with high progress and high stability (single-head and double-head optional) 3. Automatic nozzle cleaning, spray height automatic calibration, solder automatic adding function and miniaturization Design 4. AIOT intelligent manufacturing platform

2. CAM series special-shaped plug-in machine

The speed is 20% higher than that of the same type of equipment. There are many machine material stations, which can correspond to the production of various materials and small batches and multi-variety products; the equipment is small in size and flexible in wiring; the plug-in components can be bent at 15~45°

3. Small automatic partial wave soldering

? Realize reasonable and efficient production of many varieties and small quantities? Simple debugging method to ensure stable high-quality welding level ? Significantly save auxiliary materials and power consumption to achieve low-cost production ? Flexible production corresponds to saving manpower and achieving fast line change

Hangzhou Rongzhi Group

1. ASM Siemens Mounter TX2i

ASM Siemens pick and place machine TX2i: High performance and high precision in a very small footprint The ASM Siemens pick and place machine TX2i placement module sets a new benchmark for mass production. No other placement solution can achieve 25 um @ 3 sigma accuracy at speeds up to 96,000 cph in such a small footprint (only 1m x 2.3m). For the first time, you can place the next generation of the smallest components (0201 metric = 0.2 mm x 0.1 mm) at full speed like any other component. Single and double cantilever machines with a width of only 1 meter (equivalent to 3.3 feet) can be flexibly adjusted in the production line. The improved new-generation SIPLACE Speedstar placement heads always provide high performance and maximum precision placement. In cooperation with SIPLACE MultiStar and SIPLACE Twinstar placement heads, you can handle most components. The ASM Siemens placement machine Tx2 placement module is programmed using the SIPLACE Software Suite, equipped with matching feeder options and our dual guide rail , support efficient mass production, non-stop product switching and the most advanced production concepts.

2. DEK TQ printing machine

The DEK TQ is super fast (5 to 6.5 seconds core cycle time), highly accurate (±17.0 microns @ 2 Cmk), and truly space efficient. The platform is now available in two model versions, both offering outstanding flexibility: the DEK TQ for boards up to 400×400 mm and the DEK TQ L for boards up to 600×510 mm. The new three-stage operation mode, unique ASMPT NuMotion controller, fiber optic cable and cleaning process 50% faster than traditional systems ensure high-speed operation. A new belt release from the printing process and an innovative clamping system provide unprecedented precision and an exceptionally stable printing process. With a double open lid, the solder paste pot can be replaced without stopping the machine. A series of smarter functions such as the printing machine, automatic smart pin support, etc., make the printing machine can run for more than 8 hours on average without user assistance . Thanks to its numerous interfaces and supported communication standards, the DEK TQ platform can be seamlessly integrated into ASMPT’s open automation concept.

McDermott

MacDermid Alpha is a global provider of integrated electronic circuit, electronic assembly and semiconductor packaging solutions. The process solutions we provide can help manufacturer customers achieve unparalleled electronic design and manufacturing capabilities. We serve all regions of the world and every electronics manufacturing supply chain. Combined, our Semiconductor, Board and Assembly Solutions divisions team of experts collaborate in design, implementation and technical services to ensure our partner customers are successful.

1. ALPHA OM-565 HRL3 low temperature no-clean high reliability solder paste

ALPHA OM-565 HRL3 Low-Temperature Solder Paste is designed for a variety of assemblies to reduce warpage-induced defects in temperature-sensitive chip packages.

ALPHA OM-565 HRL3 achieves the goal of excellent wetting at a reflow temperature of 175 °C to minimize defects such as non-wetting open (NWO) and head pillows (HiP) during reflow.

2. UVCL solvent-free UV dual-curing conformal coating

Curing one-component conformal coating under UV light. A fast-applying and curing conformal coating designed for the protection of electronic circuits. Low viscosity; ready to use on selective spray equipment. Dual cure, the second moisture cures completely, even in shadowed areas.

Changyuan Semiconductor Equipment (Zhuhai) Co., Ltd.

1. 12-inch fully automatic Epoxy/DAF die bonder

Suitable for SIP packaging, Memory Stack Die (memory chip stacking), CMOS, MEMS… and other processes Compatible with 8-12 inch wafers Corresponding to DIP/SOT/QFN…lead frame, substrate (Substrate) and carrier board (Carrier) Glue graphics can be drawn Fast and accurate programming can achieve placement accuracy? +/-10um

2. Fully automatic QFN chip sorter

Pick & Place, CMOS Sensor, and Universal Application for products after QFN package, BGA, Tape & Saw Compatible with standard 8-inch and 12-inch standard Disco Frame, applicable to square Tape Frame (customized, optional) High output of multiple pick-up modules Output, UPH>10K High-precision pick and place: +/- 50um With front/back defect inspection and classification output standard JEDEC tray output, with optional tube (Tube) and tape (Tape & Reel) output

Xiamen Future Art Technology Co., Ltd.

In the future, Yate is committed to the construction of smart factories in the electronics industry, and professionally provides factories with smart logistics and smart warehousing overall solutions. The circulation and storage of raw materials, semi-finished products and finished products in the factory will achieve the goal of intelligent, automated and unmanned management.

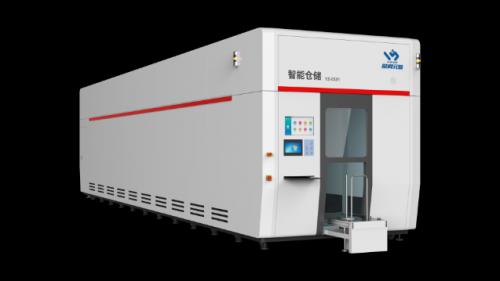

1. SMT intelligent storage

The smt intelligent warehousing is used in the smt factory to realize the full automation of the production line, and the unique design of the future Yate double robotic arm, so as to realize the more efficient and stable operation of the equipment.

2. Intelligent batching robot

It is used at the back end of the smt intelligent warehouse for discharging materials. After automatic discharging is realized, the materials are automatically placed on the shelves to the picking truck, and then the picking truck is transported to the production line by the AGV trolley.

Shanghai Zhijin Technology Co., Ltd.

1. Cloud silo

The fully automatic material management system has a newly designed batch input and output function, MIMO: MULTI INPUT & MULTI OUTPUT. The user only needs to simply place multiple trays of materials in the buffer area, and the equipment can realize automatic material identification, location search and positioning, and automatic storage. When it is out of the warehouse automatically, only the user’s work order is needed, and the equipment can store the materials in the buffer area according to the order of the station table.

2. Dosing machine

In the context of smart manufacturing or Industry 4.0, there is no doubt that the smart pointing machine needs to be interconnected with other devices. The NeoX system provides a simple way to realize information communication, material information, barcode information, point quantity, inventory, and processing Time, etc. can be synchronized with your main system through the interface.

Fujian Xingwang Yuanzhi Technology Co., Ltd.

1. AI vision SMT intelligent material cabinet

AI vision SMT intelligent material cabinet is used for high-density storage, automatic warehousing and delivery of SMT materials. Compared with traditional methods, it can better save space, save manpower, and precisely control. Different specifications can be customized according to the use environment and material business data; and the warehouse management system (WMS) can be integrated to support material preparation modes such as complete set delivery or JIT delivery.

2. AI vision automatic incoming labeling inspection equipment

This equipment can realize automatic tray labeling inspection: by visually identifying the barcode information of the tray and uploading it to the client system, a new two-dimensional code (one-dimensional code) label is automatically generated, and the blank position of the tray is automatically identified. Guide the labeling module to label, instead of manually labeling the tray. At the same time, various key parameters of the tray are compared to replace the manual inspection of IQC. The unloading mechanism supports manual unloading or automatic connection with the roller AGV.

3. AI visual assembly equipment

Xingwang Yuanzhi AI vision assembly equipment is an innovative application of AI vision technology in fastener operations. Automatic identification of products, automatic hole finding, automatic positioning, automatic locking and other operations are realized through machine learning and AI vision technology. The equipment has a wide range of applications and can meet the screw locking needs of multi-variety and small-batch production.

Shenzhen Axis Automation Technology Co., Ltd.

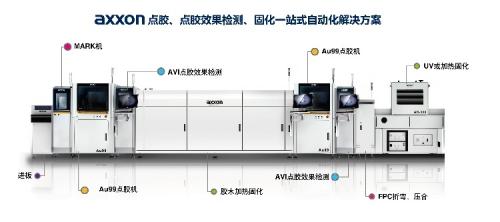

1. Overall solution for dispensing line

Axis automatic control technology conforms to the general trend of intelligent manufacturing, especially for electronic product manufacturing dispensing, and specially introduces a one-stop automatic dispensing assembly system solution. Including mark pre-recognition machine, synchronous dispensing of different processes, AVI dispensing effect detection, and identification of defective products. Among them, Mark machine and AVI are new products with independent patent rights. The configuration of the entire assembly line is designed to help customers reduce manual participation. The entire assembly line only needs one Mark recognition to maximize efficiency and improve manufacturing quality; identify products to achieve automatic program calling, foolproofing, and data statistics. So as to realize intelligent manufacturing.

2. Online jet dispensing system-Au77S

Automatic online jet dispensing system Au77S series dispensing system has obvious advantages of high cost performance, reliable and durable, simple design, suitable for multi-standard circuit boards and substrates. Equipped with simple and friendly operating software to ensure the system is stable and reliable. The system is designed for the dispensing application of chip packaging, red glue, circuit board assembly, medical supplies and other products. The width of the track can be adjusted, and it can be applied to a wider range of products. Axxon has established an extensive support and service network throughout the country to provide complete process solutions for customers’ development, manufacturing and product innovation.Product features: l High cost performance under high performance conditions l Non-contact jet valve JET7000, to achieve smaller dispensing diameter, thereby broadening the application field l Non-contact jet valve JET7000, to improve dispensing consistency and reduce Material waste, increase production capacity and yield l Mature and stable high-speed motion platform l UFD control software is easy to operate and program l Automatic loading and unloading machine can be easily integrated into application industries: l Underfill, l Dispensing red glue, l Silver paste, l Encapsulation , l surface mount, l precision coating, l semiconductor chip packaging, l Dam&Fill, etc.

3. Overall solution for Coating coating line

The overall solution of Coating coating line is the same as the manufacturing process level of the world’s leading enterprises, reducing manual participation, improving quality and overall efficiency, glue, equipment, process, testing, one-stop online surface coating system AC-800 AC- The 800 surface coating system is a high-performance coating system with its own assembly line and communication ports for upper and lower stations, which can provide you with efficient and reliable production. The control software is axxon coating software independently developed under the windows XP environment in combination with the various coating process requirements of customers in the industry. AC800 product features: fast speed, stable operation. The spray mode can be changed without interruption during work, which greatly improves the efficiency. Flexible multi-axis control can realize difficult spraying of complex PCB boards. The 3-mode spray valve with independent intellectual property rights can meet different coating needs. Strong process control ability ensures high quality and high consistency of coating. Easily realize the online selective coating function. QR code, bar code scanning, program automatic call and foolproof.Application industry: Household appliance control board Automotive electronic control board Military instrumentation circuit board Computer control board Industrial equipment control board Agricultural equipment control board Battery protection board LED control board Outdoor LED display Inverter circuit board Security control board Motor control board

*The content and pictures of the above exhibitors are provided by the relevant exhibitors

From April 13th to 15th, Shanghai New International Expo Center, meet you at the Shanghai Electronic Production Equipment Exhibition in Munich!

(Article: Munich Shanghai Electronic Production Equipment Exhibition)