Exploring “Clean Label” and Witnessing the Birth of “Five-Star Good Milk”

[ad_1]

The jasper makeup is as high as a tree, and ten thousand green silk ribbons hang down. In the beautiful season of recovery, several families of Jane Eyre tasters came to the Jane Eyre Fengning Sunshine Factory located in Fengning Manchu Autonomous County, Chengde City, Hebei Province. The author had the honor to follow in the footsteps of the tasters and jointly uncover the mystery of its “clean label” veil.

The birth of a cup of “safe milk”

At 12 noon on March 4th, after more than 3 hours of driving, the Jane Eyre Fengning Sunshine Factory with white walls and blue tiles, covering an area of more than 56,000 square meters, finally appeared in front of us. In the factory area, milk tank trucks, cold chain trucks, and workers came and went in an orderly manner, which made the author immediately feel the busy but orderly working atmosphere of this factory.

“Mom, what are these big pots?” Stepping on the viewing passage, the 11 giant milk pots immediately aroused the curiosity of the children in the same group. The lecturer Jane Eyre introduced to everyone: “Each milk tank can store more than 60 tons of raw milk. After the milk arrives at the factory, we will conduct a milk collection test within 4 hours, and only the milk that passes the test can enter the milk tank.”

In fact, the production of yogurt is not as easy as homemade yogurt. According to reports, the processing of yogurt actually includes nine major processes: “raw milk inspection at the factory, raw milk receiving and pretreatment, mixing milk ingredients, pasteurization and homogenization, fermentation, demulsification and cooling, waiting for filling, filling, and packaging”.

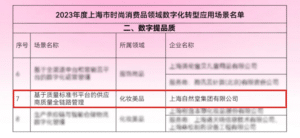

It is reported that Jane Eyre has realized the automation from raw milk receiving to filling, and has acquired, monitored and analyzed the production process data and equipment operation data through the central control system to minimize the impact of human factors on production.

When passing the filling workshop, the author learned that the filling workshop is the workshop with the highest cleanliness level in the whole factory, and maintains constant temperature and humidity throughout the year. In order to maintain the cleanliness of the workshop, Jane Eyre not only requires no less than 15 air changes per hour, all personnel entering the filling workshop also need to change one-piece overalls for the second time and enter after air shower disinfection. It is no exaggeration to say that even a strand of hair cannot be brought here.

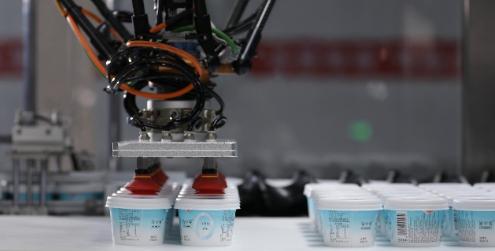

The packaging workshop is the place where a series of work such as coding and printing, scooping and capping, wrapping, boxing, film packaging, sleeve label heat shrinking, and labeling are completed after filling. Here, the product also needs to undergo a foreign object inspection before it can pass the production line.

During the visit, some attentive children found that the workers in the packaging workshop acted particularly quickly. After asking the explainer, they found out that it was because Jane Eyre required the products to enter the cold storage within 15 minutes after they were off-line. Working here can be described as a race against time, and even children can’t help but sigh: “It turns out that there are so many uncles and aunts behind the yogurt they usually drink.”

“From fermentation to filling to packaging, it is also very meaningful for children to walk through the viewing channel and see the whole process of yogurt production with their own eyes.” Consumer Ms. Huang said, “In fact, it is also very important for our parents Similarly, having the opportunity to learn about Jane Eyre’s quality standards at the production base also gave us a deeper understanding of Jane Eyre. I think the original choice was indeed right.”

What is “five-star good milk”?

Li Shengli, a professor at China Agricultural University and the chief scientist of the national dairy industry technology system, once proposed the standard of “five-star milk”. He believes that only if (1) the cows are healthy and free from diseases and infectious diseases; No external pollution; (3) Nutritious; (4) The hygiene index of milk reaches the European Union, the number of somatic cells is less than 400,000 and the number of bacteria is less than 200,000; (5) There are no antibiotics, heavy metals and pesticide residues in the milk; it can be called Real high-quality and safe milk.

Jane Eyre is catching up with the “five-star standard” through the layout of the supply chain. According to the data, Jane Eyre’s team traveled almost all over the large and medium-sized pastures in China before choosing the location of her father’s love pasture in the Bashang Grassland, which is located in the golden milk source belt at 41° north latitude, only to raise good cows and make good milk. Wei Peixuan, public food safety project manager of SGS General Standard China Agriculture and Food Department, introduced to everyone that in order to ensure a good living environment for dairy cows, SGS regularly conducts fair and objective surveys on the soil, water quality and forage of Jane Eyre’s father’s love pasture. Local testing, water quality alone needs to pass 106 tests, and pesticide residues need to pass as many as 282 tests.

At present, the key indicators of the raw milk of Jane Eyre Ranch have exceeded the EU standard, the protein content is higher than 3.3g/100g, the somatic cells are less than 150,000/ml, and the total number of colonies is less than 10,000 CFU/ml, becoming the “five-star milk” The outstanding one also makes Jane Eyre yogurt a well-deserved “five-star good milk” in the author’s heart.

Li Shengli once said in an interview with the media that domestic dairy companies need to increase innovation and upgrading in three aspects: organizational model innovation, milk source upgrading and processing upgrading, which constitute the core of my country’s dairy industry quality and upgrading innovation. , I also deeply feel Jane Eyre’s deep intentions in these three aspects. As a young dairy brand, Jane Eyre has always insisted on building a supply chain system with first-class milk sources and advanced manufacturing, which makes people look forward to its future.

[ad_2]

Source link