Cainiao launches three technology products for the manufacturing industry for the first time

[ad_1]

The “digital assistant” optimized for all scenarios (Cainiao Smart Logistics Management System), the “command center” for automation equipment (Cainiao WCS automation control system), the “smart brain” for overall supply chain optimization (Cainiao Supply Chain Control Tower)… At the 2023 Twelfth Manufacturing Logistics and Warehousing Intelligent Engineering Conference held on April 20, the “Blue Book on Mobile Robot Solutions for the New Energy Vehicle Industry” edited by the CMR Industry Alliance and the New Strategic Mobile Robot Industry Research Institute officially Released, Cainiao Logistics Technology launched three digital intelligence technology products for the manufacturing industry for the first time.

With the application of new technologies, the automobile industry is undergoing major changes unseen in a century. The strong demand for new energy vehicles in the market has also driven the wave of investment and expansion of new energy vehicle factories and parts manufacturers, and thus stimulated the demand for upstream production equipment. The “Blue Book” pointed out that as the core logistics handling equipment and process equipment, mobile robots have been integrated into most links of new energy vehicle production. Cainiao Logistics Technology’s three major digital intelligence technology products have helped many automakers achieve intelligent upgrades.

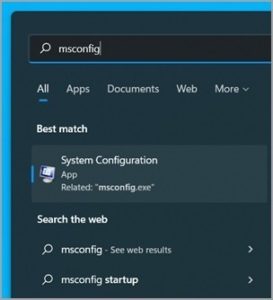

Taking Cainiao Smart Logistics Management System as an example, as a set of logistics management system solutions serving the whole scene of OEMs in the automotive industry, its functions have covered parts inbound logistics, in-plant logistics, vehicle sales logistics, after-sales spare parts logistics, etc. Four mainstream logistics business scenarios for OEMs. As an important component of the system, the decision-making analysis system can serve all transportation scenarios of spare parts, complete vehicles, and after-sales spare parts through the five centers of order center, dispatch center, operation center, settlement center, and vehicle management center, and realize the entire transportation process. Visibility and logistics ecological closed-loop management form a three-in-one logistics, business flow, and information flow; the scheduling algorithm platform can be used through the supply chain network optimization center, production capacity & network planning & digital intelligence service center, contract fulfillment distribution center, and park scheduling The center realizes the digitalization of business decision-making, and the automation and intelligence of operation management.

Figure: Cainiao Smart Logistics Management System

The “Blue Book” shows that with the rise of domestic labor costs, logistics automation has become an important means for enterprises to improve efficiency and reduce costs. However, many companies use different brands and types of automation equipment in the process of automation transformation, making it difficult to achieve coordination. Cainiao’s WCS automation control system, regarded as the “headquarters” of automation equipment, has played a positive role in realizing the unified management of logistics throughout the site and improving the efficiency and quality of logistics automation applications. The system is compatible with mainstream brands of logistics automation and can control more than 20 types of automation equipment. Based on the self-developed MAPF scheduling algorithm, the Cainiao WCS system also has the ability to schedule more than 1,000 AGVs in a single warehouse. Compared with the traditional SAPF algorithm, the path quality is improved from 60% to 98%. At present, the Cainiao WCS system has been implemented in more than 100 automation projects.

Figure: Cainiao WCS automatic control system

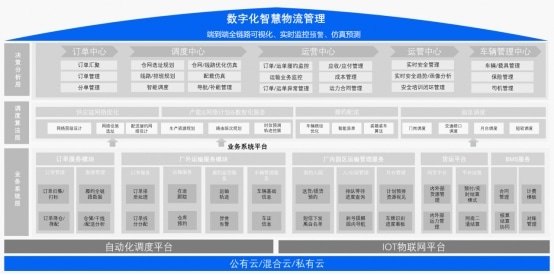

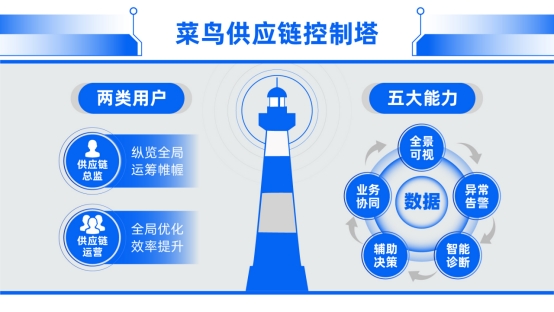

The automotive supply chain is one of the most complex supply chains. Promoting the automation and intelligence of the logistics supply chain has become the choice of many companies. The Cainiao Supply Chain Control Tower provides an effective means for businesses to better see the supply chain through data, and to help enterprises transform their supply chains into digital intelligence. According to reports, as the command center of supply chain management, the Cainiao supply chain control tower has five core product capabilities including panoramic visualization, abnormal alarm, intelligent diagnosis, auxiliary decision-making, and business collaboration. Through the Cainiao Supply Chain Control Tower, the supply chain director has a tool to view the overall situation of the supply chain, and can better plan strategies. The supply chain operation/optimization team also has a global optimization tool, which can effectively improve the overall operation efficiency of the supply chain.

Figure: Cainiao Supply Chain Control Tower

It is understood that under the background of upgrading from Chinese manufacturing to Chinese smart manufacturing, Cainiao Logistics Technology is accelerating its “into the factory”. Among them, only in the field of automobiles, Cainiao Logistics Technology has cooperated with nearly ten OEMs and parts manufacturers such as SAIC-GM-Wuling, Inovance, and Greater Group, focusing on inbound logistics, in-plant logistics, and vehicle/finished product logistics. , Spare parts/after-sales logistics and other four major business scenarios, landing dozens of projects with subdivided technical scenarios.

[ad_2]

Source link